|

ALOCODRAND® COMPOSITE is coated with polyvinylidene fluoride (PVDF) which is a high performance fluoropolymer architectural coil coating system from PPG Industries and Becker Industrial coatings. ALOCODRAND® COMPOSITE is coated with polyvinylidene fluoride (PVDF) which is a high performance fluoropolymer architectural coil coating system from PPG Industries and Becker Industrial coatings. PPG DURANAR® coating and Becker PVDF coating comprises a minimum of 70% KYNAR500® resin. KYNAR500® based finished meet or exceed the physical test performance criteria of the American Architectural Manufacturers Association (AAMA Specification 2605) for high performance coatings on aluminium panels. |

ALOCODRAND® COMPOSITE which is coated with KYNAR500® PVDF has the ability to meet or exceed the highest performance requirements of architectural coatings for :

ALOCODRAND® COMPOSITE Panels coated with KYNAR500® PVDF comes complete with a back to back performance warranty up to 10 years. |

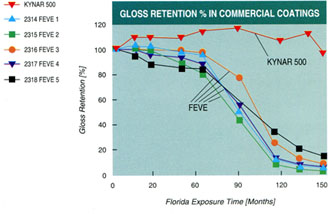

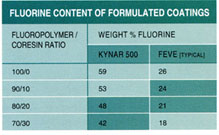

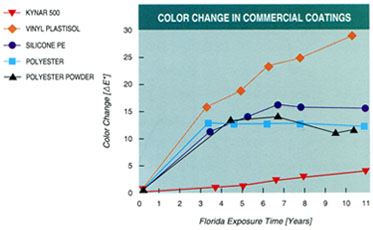

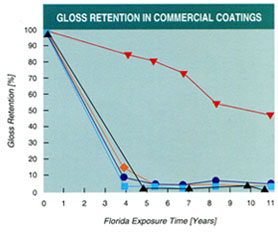

| Test show that Kynar 500 resin-based finishes outperform coatings based on the fluorpolymer resin commonly known as fluorinated ethylene vinyl ether [FEVE]. The reason: coating formulated with FEVE claim to be 100% fluoropolymer resin, but actually contain far less fluorine than Kynar 500 resin-based coating formulations. Because the C-F bond is one of the strongest bonds known, the higher percentages of fluorine content in a coating result in superior, long-term protection. The charts on this page show the fluorine content and the Florida weathering performance of the two technologies. |  |

In typical formulations [see shaded areas]. Kynar 500 resin-based coatings contain higher fluorine levels than FEVE-based coatings, resulting in greater resiliency, color and gloss retention. |

|

In applications worldwide, Kynar 500® PVDF resin-based metal coatings have demonstrated superior performance and outstanding resistance to film degradation. These coatings will withstand extended exterior exposure to water, humidity, temperature, ultraviolet rays, oxygen and atmospheric pollutants. |

The performance comparisons to the right were compiled by an independent, accredited testing laboratory and are based on actual exposure time in Southern Florida. |  |